Reclaimed wood and salvaged wood are terms that may be used interchangeably because of the similarities of their origins. However, there are often differences between the two kinds of wood planks, their characteristics, and how they can be used.

So what is the difference between salvaged and reclaimed wood?

Reclaimed wood refers to planks that have been recycled, or reclaimed, and given a second purpose after serving an initial purpose. Reclaimed wood planks can come from a wide variety of sources, including barns, old buildings, gym floors, and snow fences. We go into more detail about the sources of reclaimed wood in our Ultimate Guide to Reclaimed Wood.

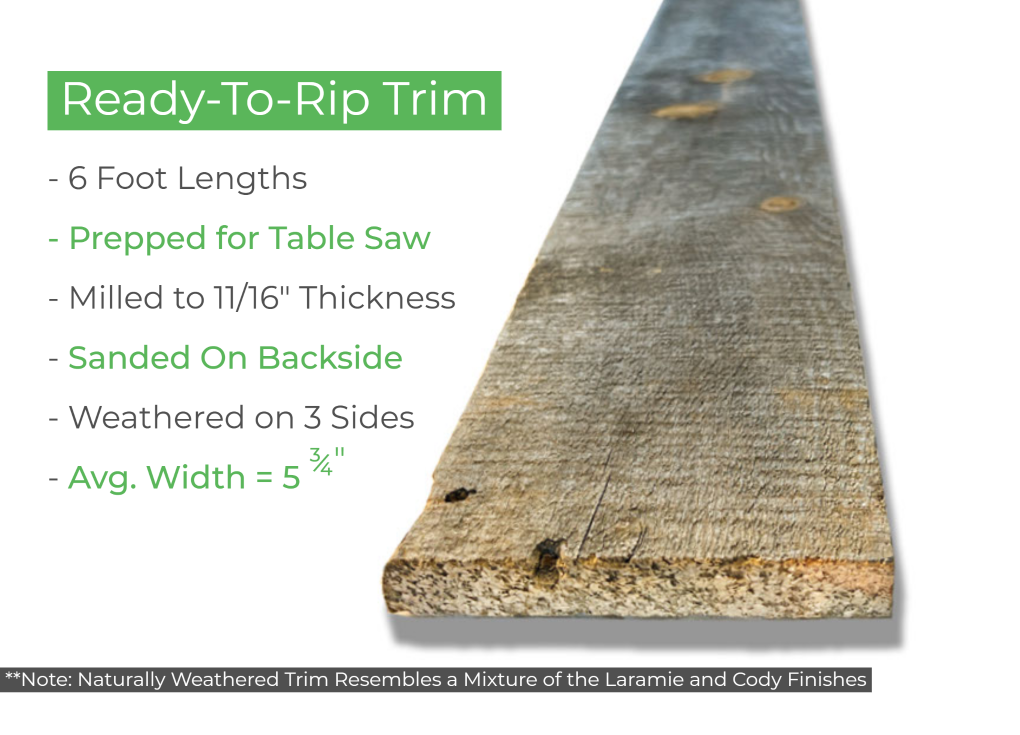

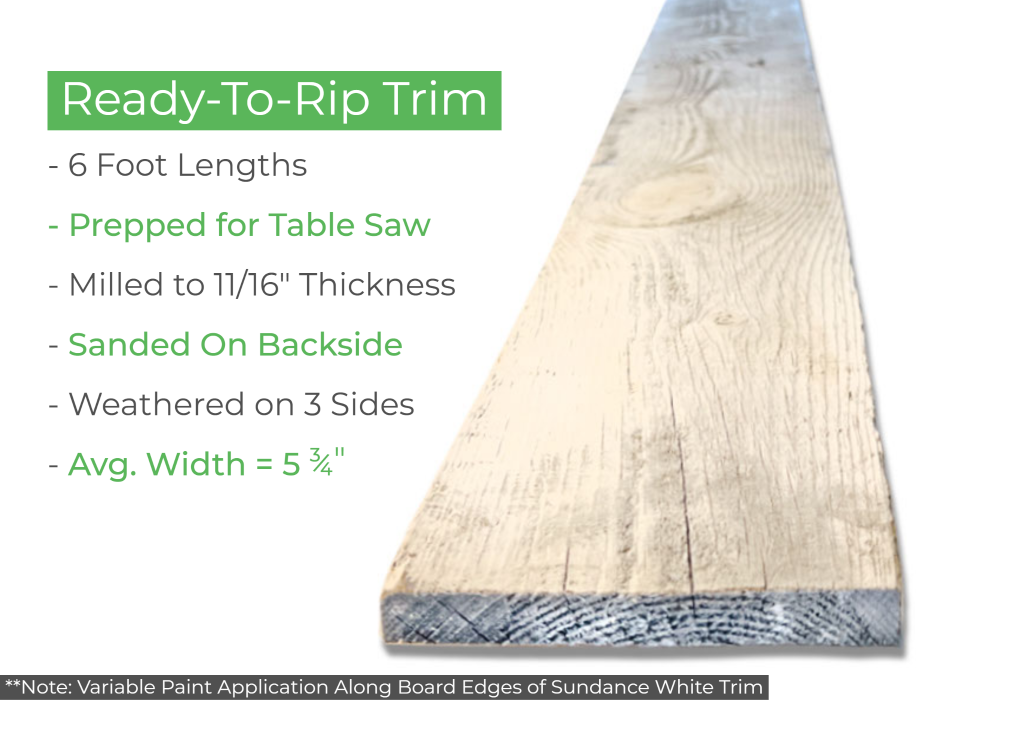

Salvaged wood, on the other hand, is typically the byproduct of a construction project or milling process. Salvaged wood planks often don’t serve an initial purpose, they’re just pieces of wood that were leftover and recovered.

But there are some exceptions to that. At Centennial Woods, for example, all of our wood - salvaged or not - is reclaimed and comes from the same source. That means the salvaged wood planks we sell were used in the Wyoming snow fences we build and maintain, just like our regular reclaimed wood.

The difference is our regular reclaimed wood planks go through our full reclaimed snow fence wood milling process, while the salvaged wood planks are just the byproducts of that process.